Energy Storage

Automotive

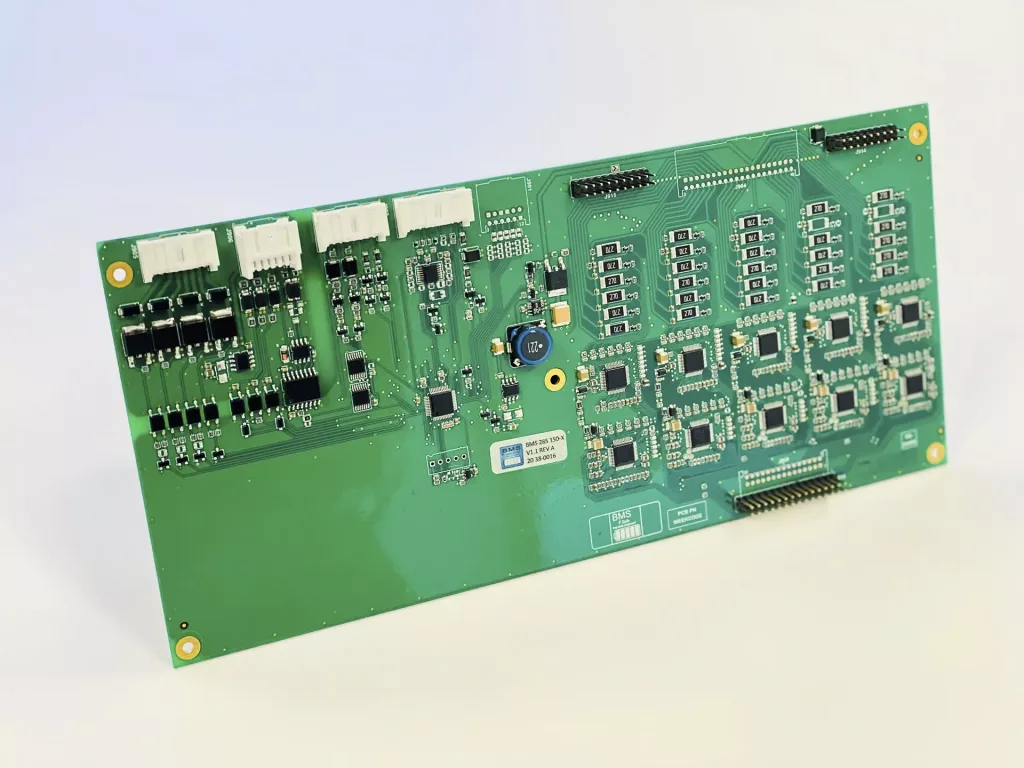

Description technique du BMS 19-30s

Cells management

- Management of 19 to 30 lithium cells in series* compatible with all cell technologies (NMC, LiFe, LiPo,…),

- Management of up to 15 NTC temperature sensors:

- 10 digital measurements used by the software

- 5 analogue measurements used by the hardware redundancy

- Measurements accuracy:

- Cell voltages: +/- 5 mV

- Temperatures: +/- 1°C

Protections

- Hardware redundancy for voltage and temperature measurements in order to reach a high level of safety (equivalent to SIL2 of EN61508 standard)

- Overcharge and undercharge, tunable by software

- Overtemperature and undertemperature, tunable by software

- Overcurrent: 2 levels in discharge, 1 level in discharge tunable by software

- Short circuit hardware protection (resettable electronic fuse)

Balancing

- Passive balancing with a 150 mA bypass current per cell (on the BMS)

Power box

- Bidirectional measurement of the battery current with a hall effect sensor

Requires contactors and hall effect current sensor- Charge and discharge management

- Power box management up to 750 A:

- Command of up to 4 external 12V electromechanical contactors

Smart functions

- SOC and SOH calculation

- Advanced self-diagnostic of the board

- Communication by CAN bus 2.0B (opto-isolated)**

- Motor controller management by CAN bus

- Charger management by CAN bus

- Advanced supervision software

- Possibility to manage a motor controller and a charger

- Advanced supervision software

- Black box integrated with defaults history storage and life counters

- Possibility to connect several packs in parallel using an external EMS (small additional board)

Power supply/consumption

- Supply of the BMS directly on the battery pack

- Low consumption in standby mode: < 500 μA

Mechanical format

- Actual format: 270 mm x 125 mm x 12 mm (possible in 210 mm x 125 mm x 12 mm)

* Factory setting

** Requires an external 12 V power supply