Lithium-ion batteries are at the heart of modern technology, used in electric vehicles, electronic devices and energy storage systems. To fully exploit their potential, while guaranteeing safety and durability, a high-performance BMS (Battery Management System) is essential. This article explores in depth how a BMS for lithium batteries optimizes performance through advanced management.

What is a BMS for lithium batteries?

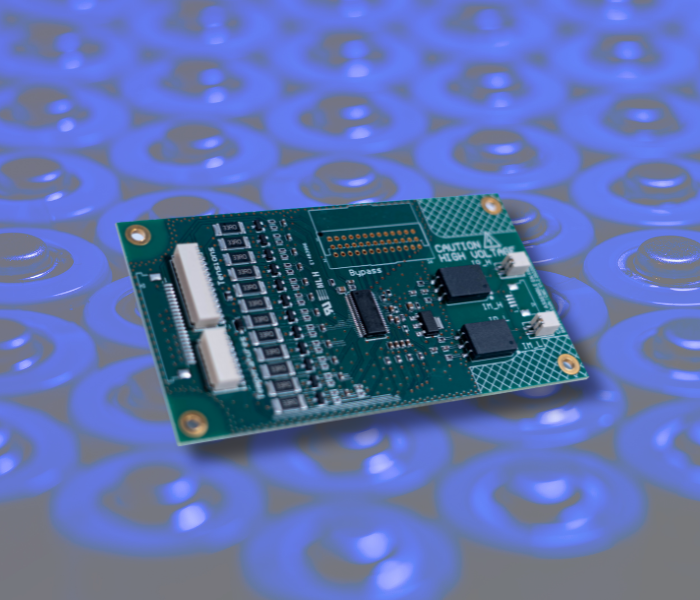

A BMS is an electronic board whose function is to manage and secure the operation of lithium-ion batteries, whatever their electrochemical composition. It monitors key parameters such as voltage, current and temperature of each cell, while balancing their charge to avoid potentially dangerous imbalances.

The main functions of a BMS:

- Cell monitoring: constant measurement of voltage and state of charge (SoC)

- Active or passive balancing: redistribution of energy between cells to maintain uniformity

- Protection: Prevention of overloads, deep discharges or short circuits

- Communication: Data transmission to the main system via CAN or UART

Why is a high-performance BMS crucial for a lithium battery?

Optimizing energy performance

Lithium-ion batteries offer high energy density, but are sensitive to variations in charge. A BMS ensures that each cell operates at its full potential, increasing overall efficiency.

Example: an advanced BMS can reduce energy losses by up to 10%, extending the range of electric vehicles.

Extended battery life

Without a BMS, cells suffer from imbalances that accelerate wear and tear. Precise balancing by the BMS extends battery life by avoiding excessive charge/discharge cycles.

Key facts: A battery equipped with a high-performance BMS can last 20-30% longer.

Increased safety

Lithium-ion batteries can be unstable if not properly managed. The BMS prevents incidents such as overheating and fire by disconnecting the power supply when anomalies are detected.

Some technological innovations in BMS design

- Active balancing: Unlike passive balancing, which dissipates excess energy, active balancing transfers energy between cells, increasing efficiency.

- AI integration: Machine learning algorithms enable the BMS to predict the battery’s state of health (SoH) and anticipate failures.

- IoT connectivity: Modern BMSs can send real-time data for remote management and predictive analysis.

Application example: IoT BMS systems are particularly useful in electric vehicle fleets, where predictive maintenance reduces downtime.

Selecting the right BMS for your lithium battery: a few tips

- Compatibility with your battery: Make sure the BMS supports the number of cells and chemistry used

- Processing power: Advanced models offer real-time analysis with complex algorithms

- Safety standards: Look for certifications such as UL, CE or ISO 26262 to ensure high reliability

Find out more tips in this article “Which BMS to select for a lithium battery?”

Are you looking for a high-performance BMS for your lithium batteries? BMS PowerSafe guarantees high-performance, safe BMS boards, adapted to your needs.

Discover our BMS boards catalog or contact us for a customized BMS design.

—

FAQ : Frequently asked questions about the BMS for lithium batteries

1. What’s the difference between an active and a passive BMS?

A passive BMS balances cells by dissipating excess energy as heat, while an active BMS transfers energy between cells for greater efficiency.

2. Can the same BMS be used for batteries of different capacities?

No, the BMS must be specifically designed for the battery’s characteristics (voltage, current and chemistry).

3. How do I know if my BMS is working properly?

Most modern BMSs incorporate diagnostics accessible via an application or monitoring system.